CNC Machining

I work as a Peer Mentor at the Bechtel Innovation Design Center (BIDC) at Purdue. I’m functionally a student machinist, and mentor users of the metal shop in the design and fabrication of their projects. I advise students on part manufacturability, tooling and work holding for their machining operations, and guide them through using the machines. I’m also on the Purdue Space Program Liquids manufacturing team, where I make flight hardware for our vehicle.

At BIDC, I’ve had the opportunity to work with manual mills, a waterjet, a Haas VF-2 and a 5 axis VF-4 mill, and Haas ST-20 CNC lathes. I’m proficient in IPS on Haas controllers.

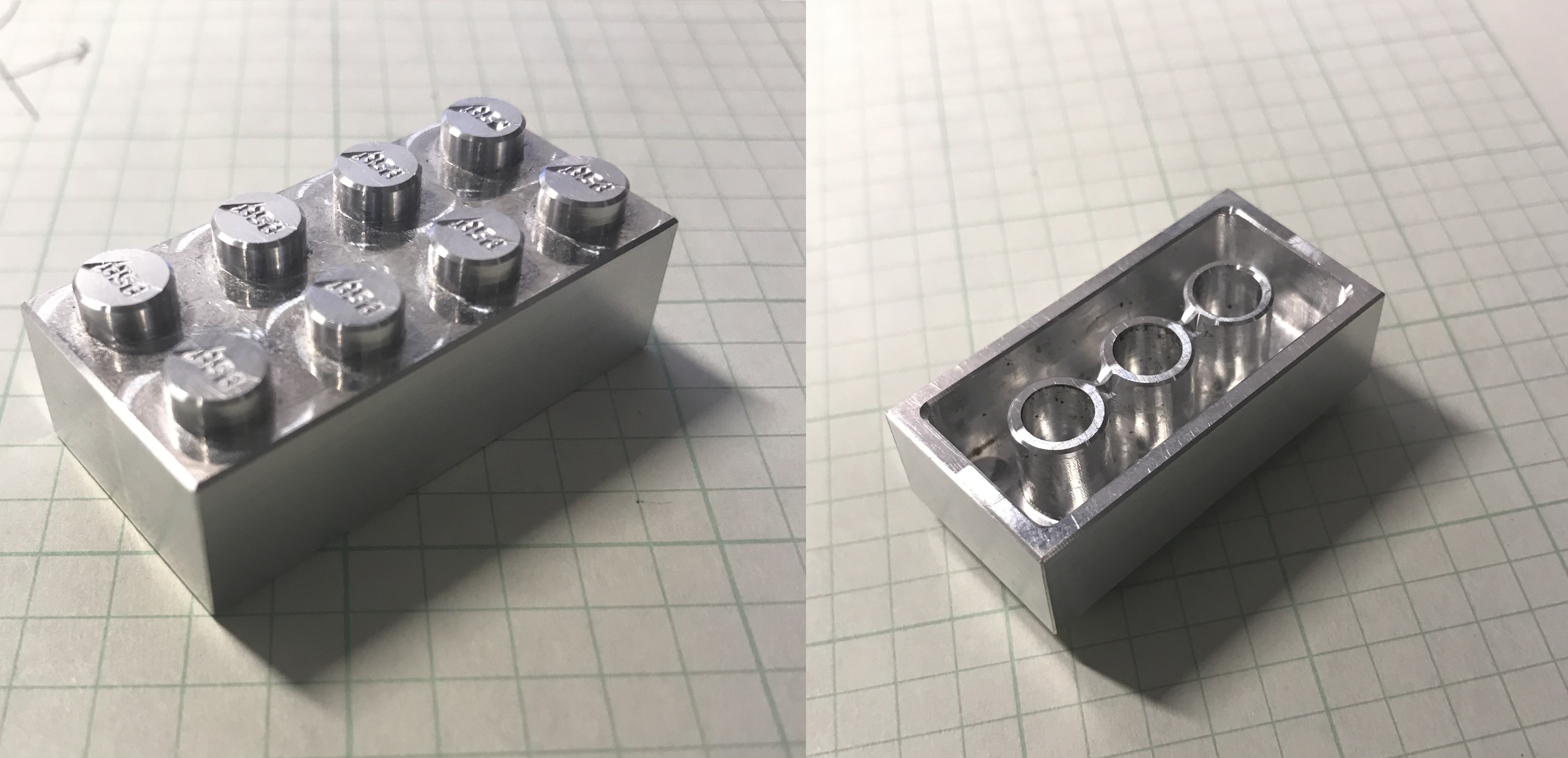

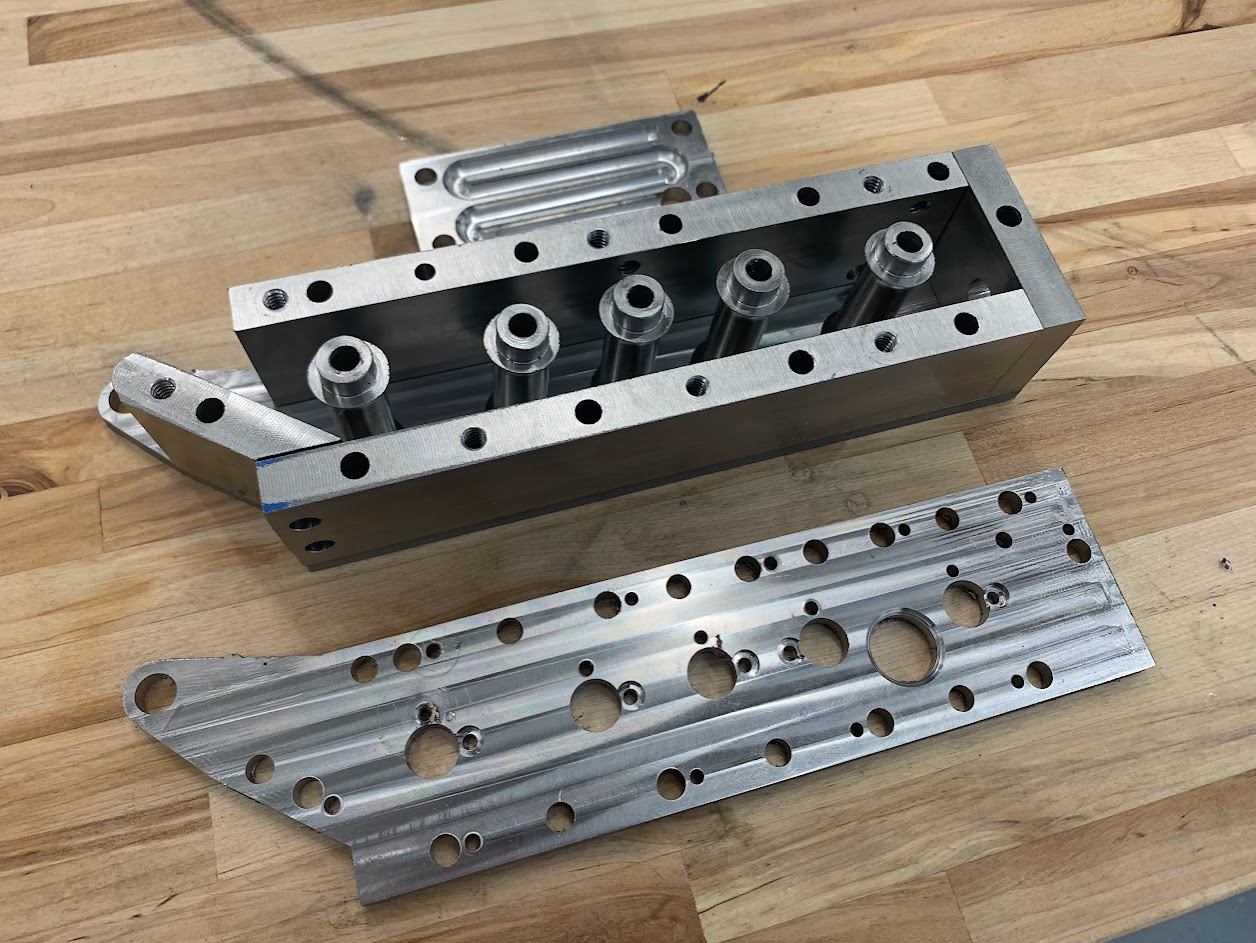

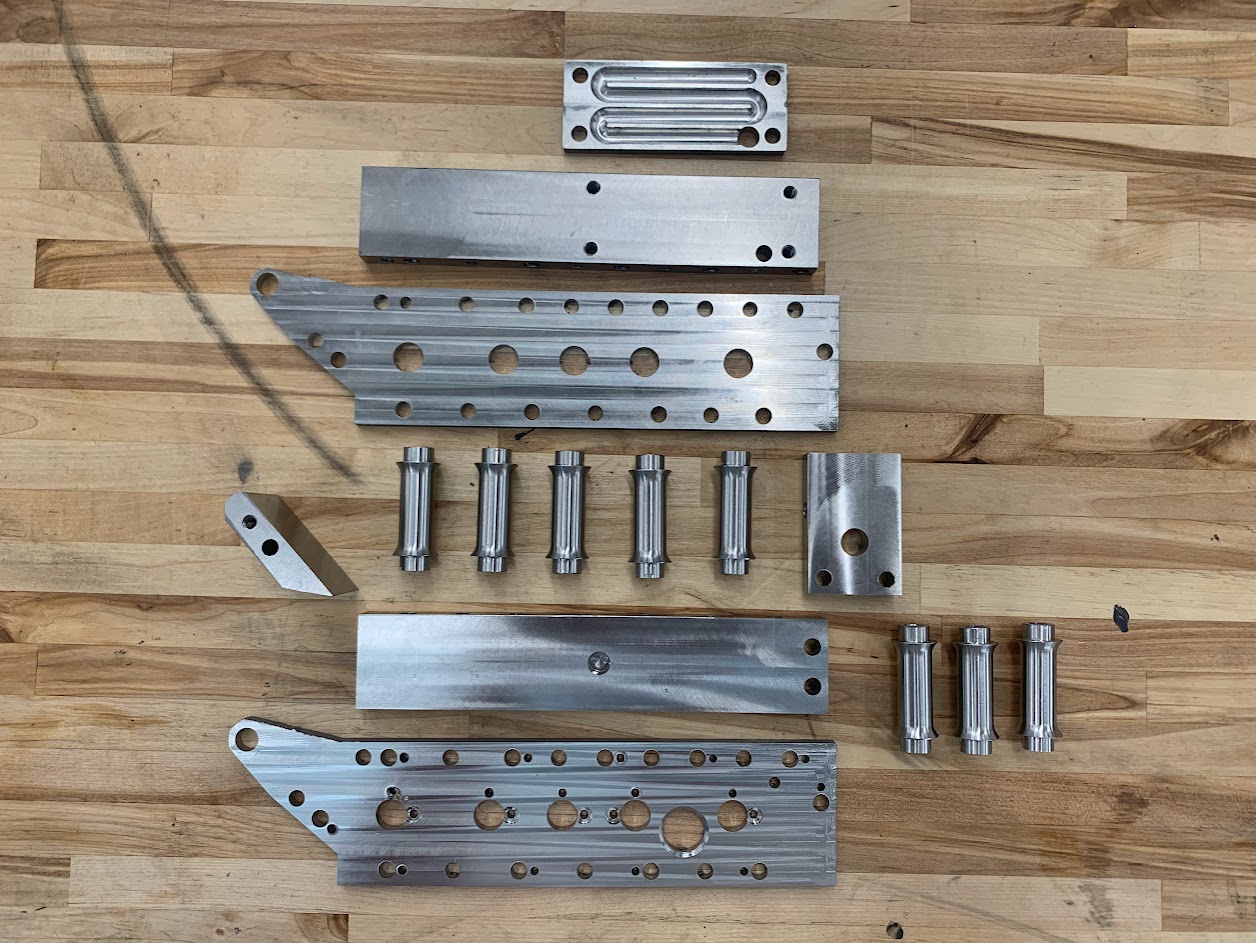

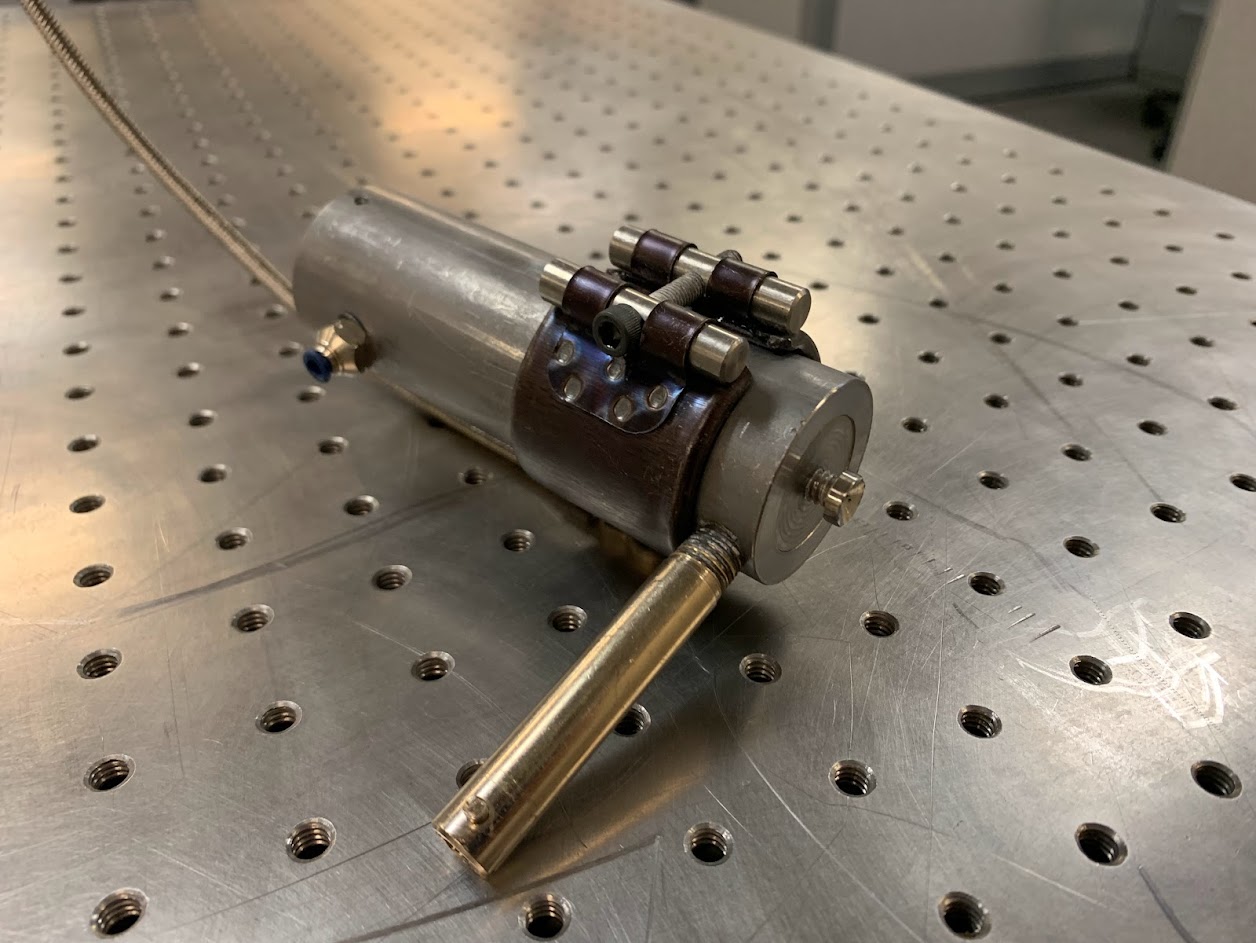

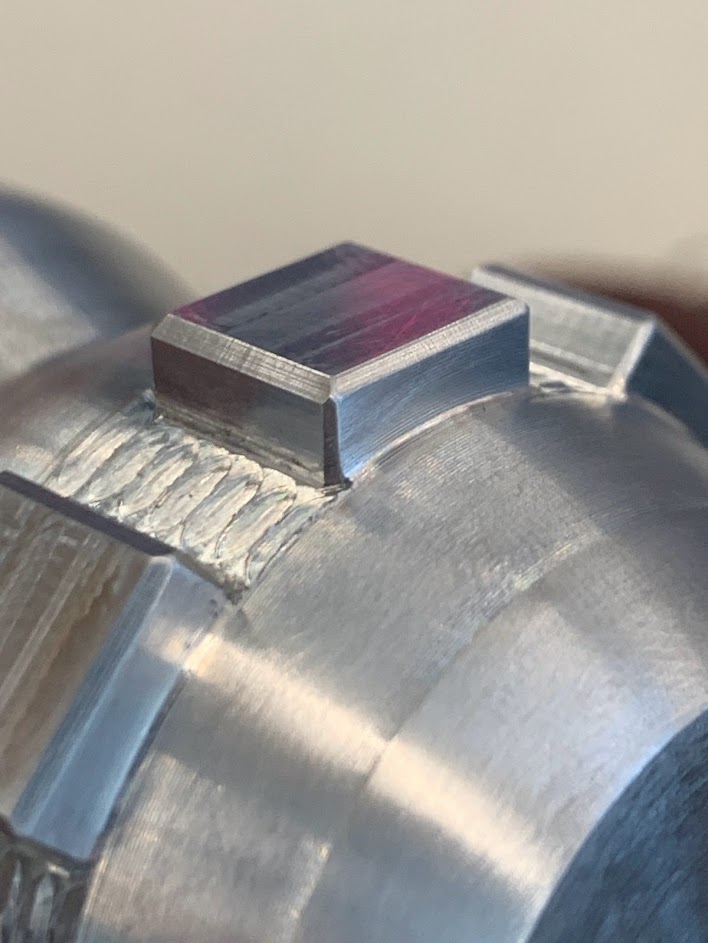

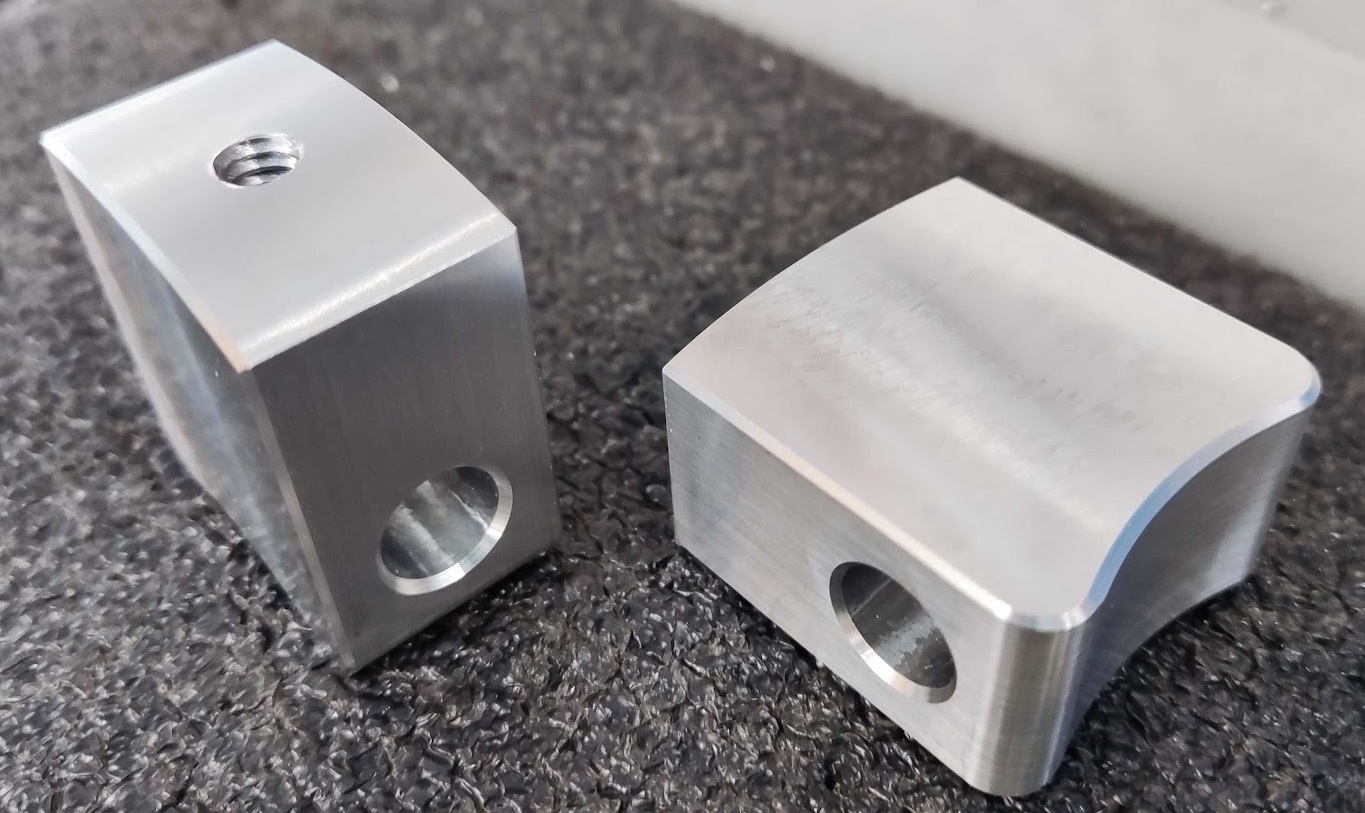

Here are some parts I’ve made:

Exterior helical channel, interior impinging orifices

Home anodized in gunmetal and silver.